Cables and Connectors are widely used today in almost all types of medical equipment – from patient monitoring systems to endoscopes, from lab analysers to Electro surgical units, from X-Ray machine to oxygen concentrators, from infusion pumps to OT Tables, hospital beds to ultrasound machines and more. Medical cables and connectors are very important and functionally critical components providing power supply, data connectivity and much more for the medical equipment. Most common problem faced by users of medical equipment with regards to cables & connectors is breakage & tear. Some damaged cables and connectors may be repairable, others may need replacement. Learn more about cables and connectors used in medical equipment. Should you need repair or replacement of any cable or connectors for medical equipment and devices like foot-switches, probes or Electro Surgical Units (ESUs) – contact us at +917019759765/ 8971223957

What are cables & connectors?

Cables – are typically a group of wires/ conductors inside a rubber or plastic jacket, which is used to carry electric power or data/ electronic signals. Medical cables carry much more than electric power and data. They may carry ultrasound waves, fluids, optical fibre, air/gases etc. – such as in a gastroscope.

Connectors – are components that link two items or devices together, such as SPO2 or NiBP cable with a patient monitor or a transducer to ultrasound machine.

Medical cables and connectors – what is special?

In the healthcare industry, medical cables may get rolled over by wheels in stretchers, wheelchair or even trolleys carrying equipment. They may get tugged on by patients and medical professionals, accidentally dropped or stepped-on. Often ultrasound probes and delicate scopes get damaged due mishandling of cables and the probe heads getting hit against hard objects. It is strongly advised to coil the cables in soft curls only, if at all. Cables often get bent or broken, as users fold cables in acute angles.

In addition, all equipment including cables need to be sterilized regularly and some equipment may need to be autoclaved. Sterilization means exposure to strong chemicals. The jacket shields the conductor and insulator from strong chemicals.

Therefore, medical cables and connectors must be capable of withstanding a variety of harsh conditions and yet be durable and not malfunction. Malfunctioning essentially means inability to provide accurate, complete and uninterrupted power and/or data.

Different types of medical cables and connectors

There are different types of cables and connectors used in medical equipment depending on the application and use.

Different Types of Cables used in medical equipment

Power Supply Cables

Most equipment and devices in any healthcare facilities require electric power to function. Therefore, power supply cables are the most commonly used cables in any healthcare setting.

A power cable mainly has three parts – the conductor, insulator and jacket. The conductor carries electric signals from the power source to the device. Insulators, insulate the user of the device from the electric current. Conductors are wrapped in insulator material. A jacket is the outer shield protecting both the insulator and the conductor, and it prevents any contact with the environment, cleaning, and sterilization components. The cable structure needs to meet FDA and the ISO 1099 requirements for human safety and protection.

Patient Monitoring Cables

These are cables that are used to measure vital parameters and transmit data signals from patient to the monitoring devices. Most common patient monitoring cables are for ECG, SpO2, NiBP etc.

Ultrasound Cable

In addition to power cables to power-up the equipment, ultrasound machines need to use high-density connectors and cables to transmit signals acquired by transducers to the processor. Transducers generate and receive reflected sound waves. These waves are converted into electric signals and transferred to the processor, where based on the amplitude and time of the echo, image of the scanned organs is produced. As ultrasound systems become more advanced and complex, more electronic channels are required. As a result cables get denser and heavier. While signal integrity is crucial for accurate diagnostics, ease-of-use of the cable is also important for the sonographer.

Endoscope

An endoscope is essentially a cable carrying fibre-optic cable with a tiny camera head. The fibre-optic cable transmits light from a light source to view internal organs. The endoscope also has air and water channels to clear any fluids inside blocking the view.

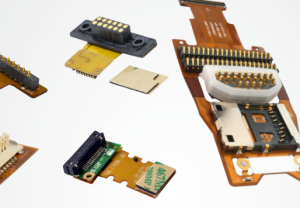

Flat flexible cables (FFC)

Flat flexible cables are extremely thin, flat cables found in high-density electronics. They are highly flexible, easy to fold, and provide a strong and reliable connection between device components.

Flexible printed circuit (FPC) and other types of cables

Flexible printed circuits (FPC) like flat flexible cables, are extremely thin and can be tightly assembled saving space and making the device compact.

Many medical equipment use micro-coaxial cables, LVDS cables and DF9 cables. DF9 cables are frequently found in hospital video displays, monitors, and HD displays.

Different Types of Connectors used in medical equipment

Connectors in medical systems such as in endoscopes, may have to carry high voltages, optical links, fluids, and power and signal lines, such as in, X-Ray/ C-Arm machines, endoscopes, ventilators & anesthesia machines, Enteral feeding tubes, NiBP cuffs, etc. Connector heads used in these applications require a high resistance to dirt and fluid invasion as well as the ability to be sterilized, easily mated without human error and unmated.

The main type of connectors seen are Push-Pull connectors and Screw-in connectors. Recent advancement include Hybrid connectors.

As medical devices and equipment become increasingly complex, there may be too many cables and connections. Hybrid connectors can eliminate the need for multiple cables and connectors. Hybrid connector can e.g. handle both power and data, improve speed of use, reliability and safety from cable entanglement and may also make device size compact. Most importantly this eliminates possibility of misconnection.

What are the common problems with cables and connectors used in medical equipment?

Cables and connectors in medical equipment are crucial for its operation. Any type of damage or failure to the cables or connectors can render the device inoperable or unreliable. The common problems with medical cables and connectors that we come across are the following:

- Cuts & tears, bends or kinks in cables.

- Broken pins in connectors.

- Fluid invasion and damage or corrosion of other components.

Compatible cables and connectors for medical equipment

Cables and connector may be repaired in certain cases. If the damage is too severe and they are beyond repair, we can help with cost effective replacement of compatible cables and connectors.

Contact us for – Cables & Connectors made for Medrad CT Injection system, Steris AMSCO surgical table hand control assembly cable, Valleylab foot switch cables, A-Scan probe cable repair and many more.

—————————————————————————————————————————

PrimedeQ is an e-Marketplace for buying, selling, renting, servicing and spares of medical equipment. We offer all types of used / refurbished medical equipment , including used ultrasound machines, X-Ray machines and other surgical equipment, endoscopes, OT equipment, Laparoscopic Equipment, Lab equipment, TMT, ECG, anesthesia machines etc. We offer repair services and spares parts for all types of medical equipment including Lab equipment, ICU Equipment, microdebrider, laparoscope , x-ray tube, rigid and flexible endoscopes as well as EUS (Endoscopic Ultrasound Units) and ultrasound probe etc.

Contact us on +91 8971223957/ 7019759765 or [email protected]

https://in.linkedin.com/in/shanthi-mathur-ab07838