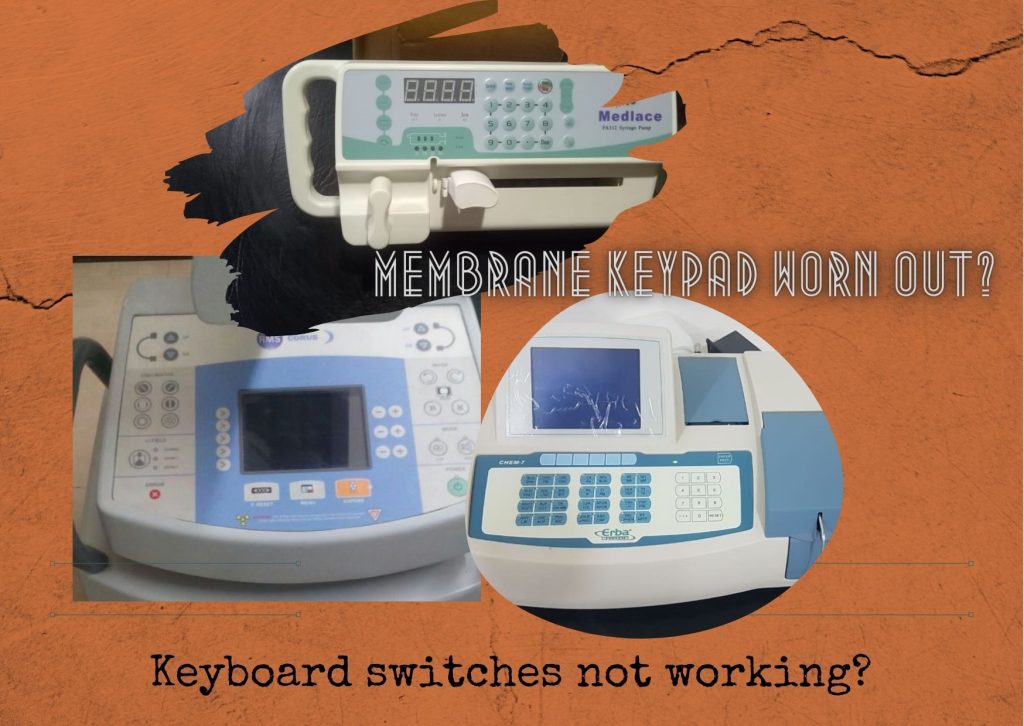

Membrane Keypads and Keyboards are widely used user interfaces today for many types of medical devices – from patient monitoring systems to hospital beds, from lab analysers to surgical equipment, from remote controls to X-Ray machine consoles, from infusion pumps to OT Tables to Cathlabs and more. They are a very important component (spare part) providing colourful and sophisticated user interface that’s user-friendly and functionally critical – to obtain patient care-giver inputs for operating the medical device. While most common problem faced by users of medical equipment with regards to membrane keypads is wear & tear, there are other significant problems such as broken membrane switches or domes, dust or fluid invasion causing corrosion etc. Some may be repairable others may need replacement. Learn more about membrane keypads and keyboards for medical equipment. Should you need repair or replacement of membrane keypads and keyboards for medical equipment and devices like infusion pumps or Electro Surgical Units (ESUs) – contact us at +917019759765/ 8971223957

What are membrane keypads and keyboards?

Membrane keypads and keyboards are interfaces for acquiring user inputs/commands to be transmitted to the electronic devices. The membrane keypad and switches can be described as an electric keypad that turns an electrical circuit on or off. At the back-end, membrane keypad is an electronic circuit that is usually printed on Polyethylene Terephthalate (PET) using made of conductors like silver / copper or graphite. The electronic circuitry is covered by a graphic overlay to received user inputs.

What is the structure of membrane keypads?

Membrane keypads and keyboards are made up of multiple layers, each having their own function. Most keypads are made of either plastic or rubber. There are usually five main types of layers – Graphic overlay, printed circuits, adhesive, spacer and fillers/buffers.

- Graphic overlay is the top-most and visible layer of the membrane keypads. This consists of graphically represented operating instructions. It is used for acquiring user inputs and also offering some protection to the layers underneath. The graphic overlays are usually printed digitally or screen printing ink on one side of coated polycarbonate or PET substrate.

- Beneath the graphic overlay, there are multiple layers consisting mainly of electronic circuits, metal domes, buffer, spacers and adhesive layers bonding the graphic layer to other layers on the membrane keypad.

- Finally there are connectors linking the circuits to the medical device.

Learn more about structure of membrane keypads in details in the following blogs

Membrane keypads and keyboards for medical equipment

Membrane keypads and keyboards are widely used in medical technology in various equipment ranging from patient monitoring systems to hospital beds, from lab analysers to surgical equipment, from remote controls to X-Ray machine consoles, from infusion pumps to OT Tables to Cathlabs and more. Medical equipment operation must be error-free and efficient, other-wise there could be adverse impact on patient safety and care. At the same time, sterility and infection-control is of highest importance in healthcare set-ups. Hence, strong cleaners may be frequently used to sterilise equipment used in clinics, hospitals as well as other healthcare facilities to stop spread of infection, impacting the membrane keypads.

Some membrane keypad technology use graphic overlay made of textured polyester that incorporates antimicrobial substances to help with sterility, while offering a tough overlay that is able to withstand repeated contact with harsh cleansing solvents.

Some of the specific requirement for membrane keypads and keyboards used in medical equipment (different from computers and gaming devices etc.) include:

- Graphic overlay – As mentioned earlier, medical equipment user interfaces should be easy to use and error-free. A graphic overlay can be viewed in a 180° angle, something not possible with touchscreens. This is of great convenience to surgeons in operating theatre, needing to use equipment (such as C-Arm) while operating on the patient lying on the surgical table.

- Sterilization – Proper medical equipment sterilization is crucial for infection control best practices in hospitals. Fully-sealed, smooth surface, membrane switches are easier to clean, compared to mechanical switches with raised buttons. Anti-microbial films that provide built-in germ-fighting protection are also useful.

- Compact form-factor and fully sealed designs –Fully sealed membrane keypads also withstand exposure to water, chemical, bodily fluids, dust, and other elements that are harmful to electronics. A compact form factor of membrane switches and unique size specifications may be needed for accommodation into small medical devices or devices with little flat surface.

- Shielding – Membrane switches can be designed to include shielding elements to block electrostatic discharge, preventing electric interference adversely impacting performance of other electronic equipment in the vicinity.

What are the common problems with membrane keypads?

Membrane keypads and keyboards for medical equipment are crucial for operation of the device. It is evident that any type of damage or failure to the membrane switches can render the device inoperable. The common problems with membrane keypads that we come across are the following:

- The most common cause requiring replacement of membrane keypads and keyboards for medical equipment, is wear & tear or discolouration of graphic overlay or springs failure, due to long period of use.

- Equally frequent problem is malfunctioning of membrane switch due fluid, dirt/dust or food crumbs invasion into lower layers causing damages to circuit or other parts.

- Breakage or displacement of metal domes is another problem seen in membrane switches.

- Adhesive layer may come-off of the device or other layers resulting in the membrane becoming ineffective.

- Damage to printed circuitry could happen in extreme cases.

Compatible membrane keypads and keyboards for medical equipment

Membrane keypads and keyboards may be repaired in certain cases. If the damage is too severe and the keypad’s membrane is beyond repair, we can help with cost effective replacement of compatible membrane keypads and keyboards.

Contact us for – Membrane keypads and overlays made to fit Baxter infusion pumps, BD infusion pumps, Smiths Medical syringe infusion pumps, Conmed ESU, Fisher & Paykel Humidifier, Fresenius Hemodialysis Machine, GE MAC ECG machines, All types of membrane switches and overlays for remote control and control compatible with Hill Rom Medical Beds, Medrad Angiographic Injection systems, Valleylab Force ESUs, Mindray Ultrasound machines, Neuvoment Ventilator, Philips Respironics Bipap, Patient monitors, ventilators, Philips HeartStart Defibrillator, Philips IntelliVue monitors, PhysioControl Lifepak defibrillator, Zoll Defibrillators and many more.

—————————————————————————————————————————

PrimedeQ is an e-Marketplace for buying, selling, renting, servicing and spares of medical equipment. We offer all types of used / refurbished medical equipment , including used ultrasound machines, X-Ray machines and other surgical equipment, endoscopes, OT equipment, Laparoscopic Equipment, Lab equipment, TMT, ECG, anesthesia machines etc. We offer repair services and spares parts for all types of medical equipment including Lab equipment, ICU Equipment, microdebrider, laparoscope , x-ray tube, rigid and flexible endoscopes as well as EUS (Endoscopic Ultrasound Units) and ultrasound probe etc.

Contact us on +91 8971223957/ 7019759765 or [email protected]

https://in.linkedin.com/in/shanthi-mathur-ab07838