PrimedeQ offer QA services for all types if radiation equipment. We also assist hospitals and diagnostic centres with ELORA registeration, AERB licensing, TLD badges etc. Contact us on +917019759765 or +918971223957 or write to us at [email protected] for any assistance in this area.

QA essentially involves testing of all the exposure parameters to ensure accuracy of measurements as well as to check functional performance of X-ray equipment. Functional performance of the X-Ray equipment is checked on various fronts to ensure proper functional alignment and delivery overall to achieve the main objectives of QA.

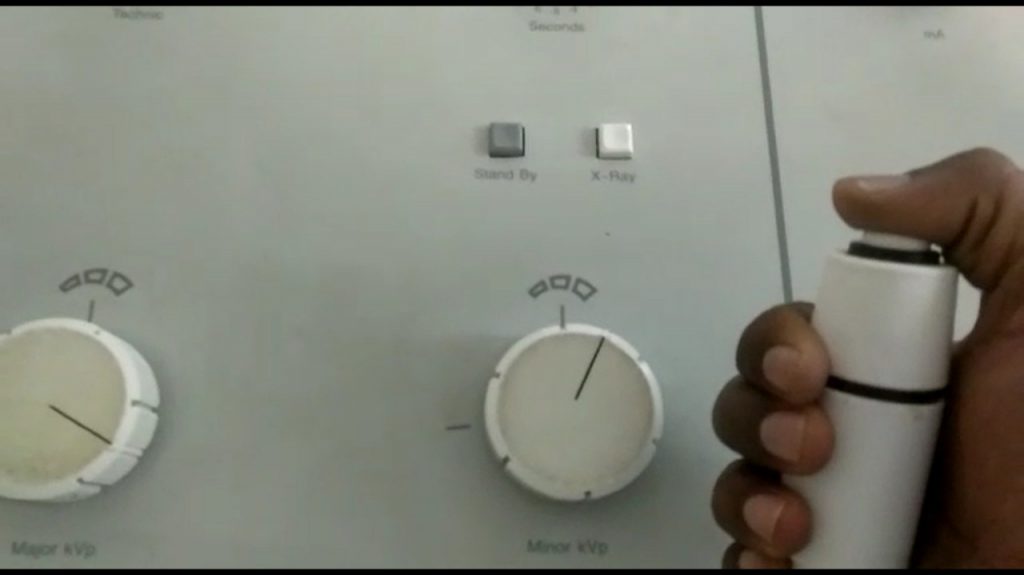

kVp, mA and exposure time are the exposure parameters of x-ray unit on which output of x-ray unit depends. Including the above, the various parameters affecting image quality are:

- Operating Potential

- Operating Current

- Exposure Time

- Effective Focal Spot Size

- Total Filtration

- Leakage from tube housing

- Detector Characteristics

What is actually done in a QA test?

To ensure main objective of achieving – high quality image, in an energy efficient manner, with minimal radiation exposure to patient, technician as well as general populace – the following QA tests are carried out as per AERB stipulations:

- Congruence of radiation and optical fields – The X-ray field must be aligned with the light field so that the operator can accurately position the body part to be imaged. If the optical field and radiation field are not congruent, the area of clinical interest may be missed in the radiograph leading to retakes and unnecessary radiation exposure to patients.

- Central beam alignment – If the x-ray beam is not perpendicular to the image receptor, the image may be distorted. The distortion will be further magnified, if grid is used leading to significant loss of minute details.

- Effective Focal spot size measurement – What is the role of focal spot in image quality?Focal spot is the area of the anode surface which receives the beam of electrons from the cathode. A small focal spot is used when more details within smallest image is important to see, while a large focal spot is employed when a short exposure time is the priority. To produce sharp images, focal spots need to be small but heat loading on the tube is high. Effective focal spot length may be smaller depending on the anode angle. Tube life may be compromised if effective focal spot size is lesser than actual for extended period of time. Hence periodic QA is necessary.

- Timer Accuracy – If timer is not accurate then the exposure time can be more or less than desirable. If the exposure time of the x-ray unit is not in order, the radiograph can be under exposed or overexposed.

- Accuracy of Accelerating Tube Potential – The peak potential of the x-ray generator affects quality of the x-ray beam and exposure to the patient. Assessment of the tube potential ensures that the delivered kVp is close to that set on the equipment by the operator.

- Linearity of radiation output – The tube current (mA) is equal to the number of electrons flowing from the cathode to the anode per unit time. The exposure of the beam for a given kVp and filtration is proportional to the tube current. This test is carried out to check the linearity of radiation output with respect to change in tube current (mA) stations by keeping timer station constant at a particular kV station.

- Reproducibility of radiation output – To check the constancy of radiation output. Keeping tube current and exposure time fixed, radiation output is measured at various available kV settings. Consistency at each kV station is checked by evaluating the coefficient of variation.

- Total filtration – The purpose of filtration is to cutoff low energy components from X-ray beam, which do not contribute to diagnostic image formation but result in unnecessary patient exposure. If the filtration is too high, image contrast will be poor and unit will be overloaded. Therefore it is necessary that the total filtration (inherent + added) provided for the X-ray tube be as per the recommended value.

- Radiation leakage through tube housing – It is obvious that un-intended leakage is harmful to everyone around, hence to be eliminated. The radiation leakage measurement is done using a survey meter.

- Exposure rate at tabletop – The distance separating the target of the x-ray tube and the top of the fluoroscopic table has an important effect on many of the operating characteristics of a fluoroscope. Among these are (a) the exposure dose rate delivered to the region of the table top, (b) the integral dose rate received by the patient, (c) the magnification and sharpness of the fluoroscopic images, (d) the exposure time for spot-film radiography, and (e) the heat generated within the x-ray tube. Hence for Flouroscopy equipment this is an important parameter to be checked.

- Fluoroscopic image quality parameters

- High Contrast Resolution or Spatial Resolution – refers to the ability of imaging system to visualize small details in the image captured.

- Low Contrast Resolution – Low contrast sensitivity refers to the ability of an imaging system to visualize low-contrast objects or structures that differ slightly in radio-opacity from the surrounding area.