“It is very important to understand that there is a big difference between high-quality refurbishment to the Original Equipment Manufacturers’ (OEM’s) specifications and second-hand equipment of undefined quality.” says COCIR, the European Coordination Committee of the Radiological, Electromedical and Healthcare IT Industry. A used equipment may not be as economical to use and may compromise patient safety. A well-refurbished medical equipment e.g. ultrasound machine delivers as good as a new one.

A set of rules have been put together by COCIR that would contribute significantly in extending equipment’s shelf-life without affecting safety, while reducing environmental impact and contributing to the recycling economy.

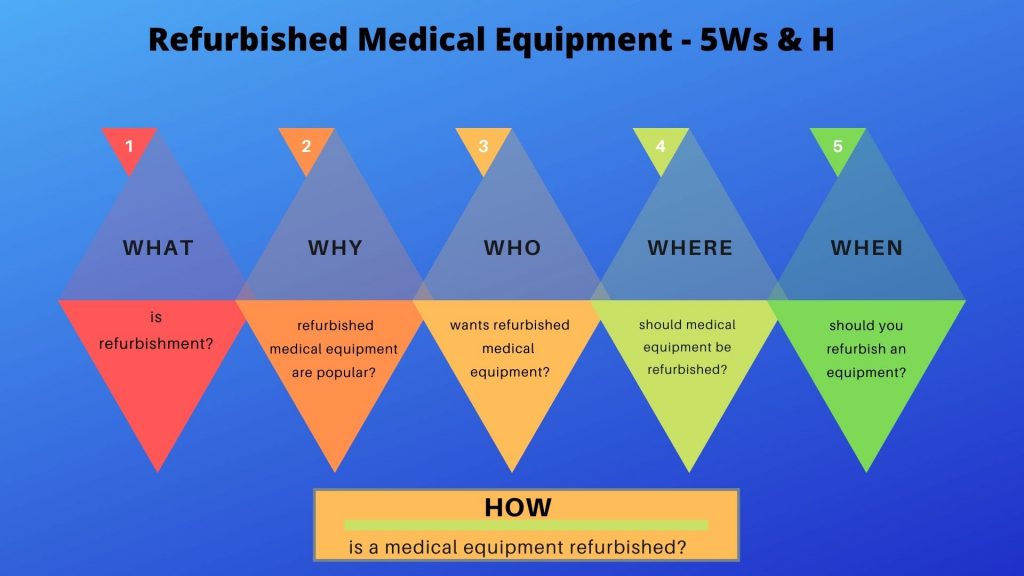

How is a refurbished ultrasound machine different from a used or second-hand one? What is the difference between repair and refurbishment? Why is going for a refurbished medical equipment a good idea? What should a good refurbishment centre have? How is medical equipment refurbished? Let’s look at answering all these questions here.

What is refurbishment?

Refurbishment is a systematic process bringing used equipment to the same condition as new or even better. What is the difference between “repair” and “refurbishment”?

- Repair is to restore to good working condition – if the machine has broken down. It means to fix damage or to mend something broken or to remedy, if there is a problem. Repair does not make equipment as good as “new”.

On the other hand…Refurbishment means – To rebuild or renew with all new material, components or parts; to restore to original (or better) working order as well as appearance. - A used or second-hand machine may be presently in good working condition. It may however, have some worn-out parts and hence has higher probability of breaking-down anytime. A refurbished machine has less chances of break-down just like a new one.

Why refurbished medical equipment is popular?

Some equipment are very sturdy and popular among users. They have had a long run in the market with few upgrades. Take for example an ultrasound machine like GE Logiq P5 which was launched in 2005 and is still very popular in 2021. Such machines could be used for at least 5-7 years or more, if refurbished well. For budget conscious users a good refurbished machine is a great option. High value imaging equipment like refurbished CT, MRI, Cathlabs, PET CT, Ultrasound machines etc., are highly sought after.

Benefits of Refurbished medical equipment

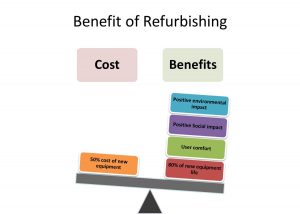

Refurbishing a medical equipment means extending the life of the equipment, normally from 5/7 to 10/14 years or even more, therefore it is in a way reuse and waste prevention. This also saves the energy and the materials used to produce a new device.

- Apart from these important environmental benefits, refurbishing also provides sustainable economic benefits by creating business and employment in the refurbished medical equipment sector. Therefore we can safely say that refurbishment of medical equipment provides for important benefits both from an environmental and social perspective.

- Even existing equipment owners may consider refurbishing their machine rather than disposing it–off and buying new, if their users are comfortable using the specific model. Refurbishment typically costs about half as much as buying new and can bring a machine back to like-new condition. In addition to the initial cost savings, refurbishment increases resale value and can provide tax benefits to a business, depending on how it’s structured. A refurbished asset can be re-capitalized on a depreciation schedule at half the value of a new machine.

- Apart from cost savings, user comfort with the machines they’ve been using is a bonus. Refurbishment not only eliminates the annoying problems faced in using a worn-down machine, it also avoids the learning curve associated with new equipment. Users often grow fond of their machines and love to see their trusted old machine brought back to life, in better shape than before. Refurbishment also sometimes gives the opportunity to upgrade to the newest available technology.

In financial terms – if you can extend life expectancy of the machine by about 80% of a new equipment, with just about 50% of the cost of new equipment – What can be a better deal?

Who wants refurbished medical equipment?

Small & medium hospitals, typically doctor-owned and less-than 100 beds, often cannot afford to buy new high-end equipment. They prefer refurbished equipment of reputed brands that will cost less but perform well for a few years without complaints. These may be young doctors starting out on their own after working with such equipment in larger hospitals. They may be familiar and comfortable with the model of the equipment, but do not have the budget in starting stages of their venture.

Also tier-3 towns may have enough patient volumes, but without sufficient paying capacity. Such places cannot offer enough Return on Investment (ROI) on new equipment

Nearly 1/3rd of the medical equipment market in India constitutes used/ refurbished equipment, specifically of the above category of buyers.

Where medical equipment should be refurbished?

It is important to choose a refurbishment centre that has standards equivalent and necessary to restore the equipment to OEM specifications. Check if the refurbisher has

- Established procedures – necessary for quality checks and testing

- People – trained in the OEM equipment and refurbishment processes with capabilities to ensure compliance with specifications that match that of new equipment.

- Tools & facilities – needed for inspection, cleaning & disinfection, dismantling, testing, calibration, repair, replacement, restoration, assembly, packing and re-installation.

- Original spare parts stock – needed to replace and offer warranties

OEM refurbished machines are definitely the best option since it is the same people manufacturing these equipment in the first place. However, there are also equally competent and well-equipped third-party refurbishers in the market. A good refurbisher will also have the confidence to give standard warranties as well as service support, on the equipment refurbished by them.

When to refurbish – when refurbishment is appropriate for a machine

Refurbishment, if done at the right time, on the right equipment, and by the right people, can provide significant cost savings when compared to buying new. Although it would be convenient to be able to say a machine is best-suited for refurbishment after it has run for a certain number of hours or years – such a statement is too general. The type of machine, the age of the machine, and the application in which the machine has been used all play important factors in properly timing a refurbishment.

Importance of Equipment Selection in refurbishment

Not every used system is suitable for refurbishment. The selection of used equipment for refurbishment is based on whether it can be refurbished to a system that has the same quality, performance, safety and intended use as when it was new – at a reasonable cost.

A thorough inspection is done before selecting a system mainly to check:

Type & configuration

Is the model, version and configuration is in demand. How current is the technology. An out-dated technology level may either require too much work or may not even be upgradeable to saleable technology configuration.

Age, condition & upgradeability

- In terms of age – generally equipment in its mid-life is preferred.

- Condition – Let’s categorise equipment from Tier 0 to Tier 4 – Tier 0 being “to be condemned” and Tier 4 being “as-good-as-new”. Evidently, bringing a Tier 2 machine to Tier 3 level could be affordable. Bringing a Tier 0 machine upto Tier 4 may just cost too much. It may instead be better to buy a new machine. Stringent selection standards ensure that only those systems with well-known and acceptable service histories qualify for refurbishment. Equipment that has experienced high usage or has been poorly maintained is generally avoided.

What are the common failures encountered in ultrasound machines? Failure analysis of more than 100 ultrasound machines in a study showed that there were 33 cases (30.5%) due to software, 44 cases (40.7%) due to hardware, and 31 cases (28.7%) due to Ultrasound probe.

Phase in the life cycle of the system

The phase in the lifetime of a system is generally defined by spare part availability. Shortage of spare parts limits the ability to service a system. Hence, it is an important selection criterion for refurbishment. If an OEM has already declared the model end-of-life, spare part production and hence availability may slowly start getting difficult.

How are medical equipment refurbished?

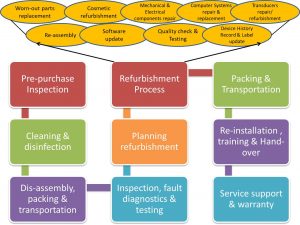

The goal of a refurbishment process is to restore the medical equipment to working condition and appearance of a new one. A good refurbishment process involves

- Right equipment selection,

- Cleaning & dis-infection,

- Professional dis-assembly, packing & shipment to refurbishment centre in such a manner so as to avoid any damages.

This is followed by

- thorough inspection, testing and fault diagnostics at the centre.

- Once the equipment has been thus studied – a refurbishment plan is prepared.

The key steps in refurbishment process involves – replacement of worn-out parts, mechanical, electrical & computer hardware repair or replacement. Thereafter software upgrade is done as required, proper cosmetic refurbishment, professional re-assembly, packing and shipment to new destination. Re-installation, system performance check, training & handover at client site is also to be done just the same as for a new one.

After Sales Service & Warranty – Most OEMs offer 1 –year warranty for refurbished systems and promise of original spare parts availability for a minimum of 5 years.

Click here to read all about a good refurbishment process for medical equipment in full detail.

——————————————————————————————————————————-

PrimedeQ offers all types of used / refurbished medical equipment on Sale, including X-Ray, TMT, ECG, anesthesia machine, ultrasound machines, endoscope and ultrasound probe repair services etc. Contact us on +917019759765 or +918971223957 for any medical equipment or related spares & services. Click here to buy or sell used or refurbished Ultrasound machine or Ultrasound probe/ transducer

https://in.linkedin.com/in/shanthi-mathur-ab07838